Krix Loudspeakers is a South Australian company with a near fifty year heritage of design and manufacture of loudspeakers. Starting out with Hi Fi loudspeakers, Krix have broadened their range to include home cinema, concealed audio, high end cinema, and commercial cinema. Krix now supplies speakers to most of the major commercial chains in Australia and exports to over 30 different countries.

An important aspect of sound systems for commercial cinema is control of the directivity of the loudspeaker system, and Krix systems have very good behaviour in this characteristic. Krix have been designing acoustic horns using Finite Element Analysis techniques since 1999 to achieve exemplary directivity performance. Since 2008 Krix has used COMSOL, from 3.5 to the present version.

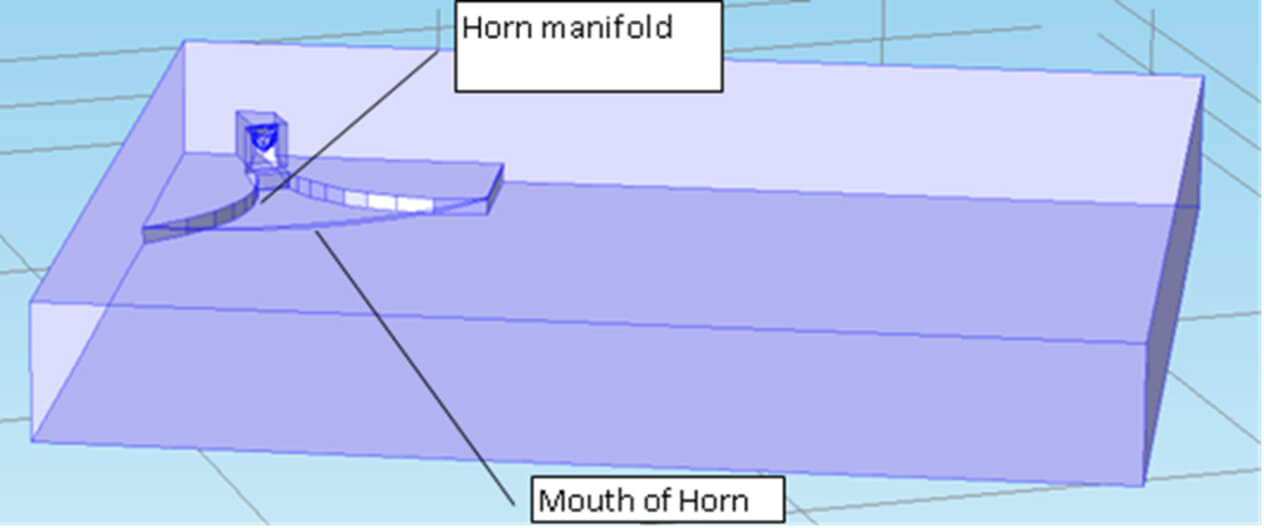

Loudspeaker systems for commercial cinema deploy acoustic horns for midrange and high frequencies, large direct radiator 300 litre enclosures for low frequencies, and even larger direct radiator 500 litre enclosures for the sub woofers. Behind the screen are left, centre and right horn loaded loudspeaker systems and sub woofers, and on the side and rear walls are multiple surround loudspeakers.

Over the last 20 years Krix has developed a range of acoustic horns, wave guides and low frequency enclosures to supply appropriate acoustic outputs to almost any size of cinema. The largest so far has been in Deira, Dubai, the screen being 31 metres wide, the cinema depth being 38 metres! Because of the width it used five screen systems.

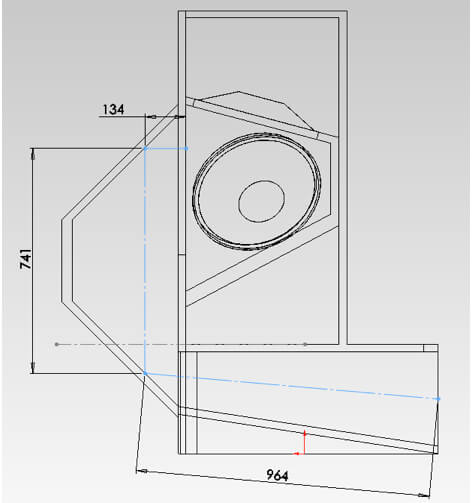

In the good old bad old days, acoustic horn designers would select a throat size, a mouth size, a lower cut off frequency and calculate a suitable exponential profile. A prototype could be laboriously fabricated and acoustically measured to ‘verify’ the design. There was usually a passing resemblance between calculated and measured results, so a redesign and another laborious fabrication was required. Accurate fabrication, especially for large format horns of mouth size 700 mm by 800 mm and depth 750mm, consumed several hundred hours of work.

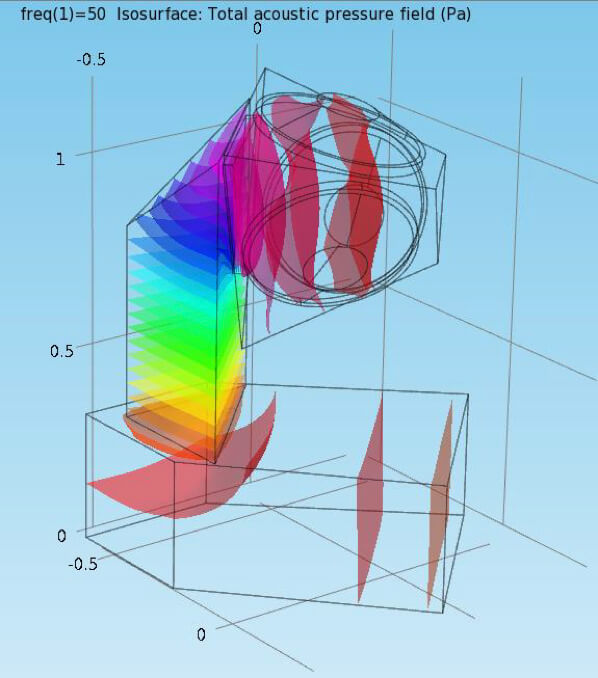

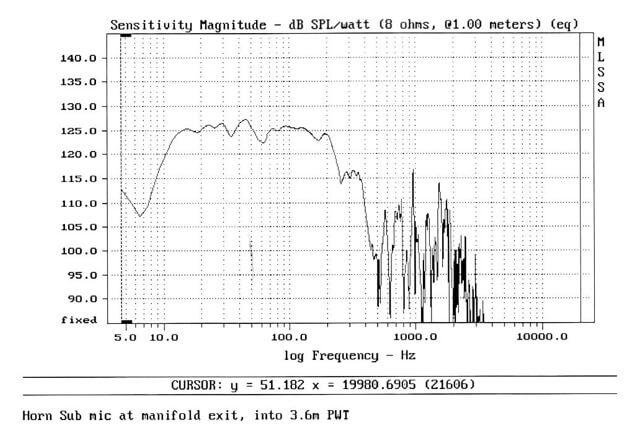

Krix purchased FEA software, developed a suite of macros to draw a horn shape, draw air in and around it, precariously mesh the volume, and do a frequency run. The results were saved and post processed to obtain polar responses in horizontal and vertical planes, and graphs of the beam angles (-6dB angles) versus frequency. Turn-around time using overnight simulations was two or three days, much faster than before.

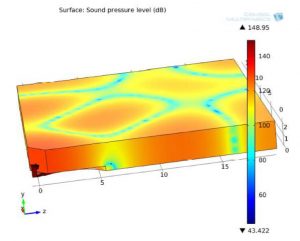

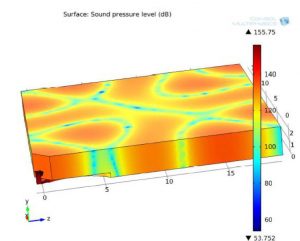

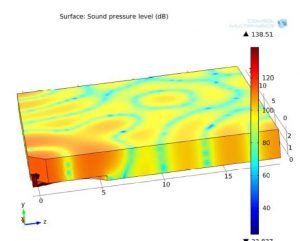

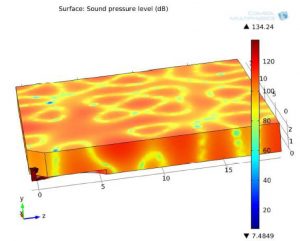

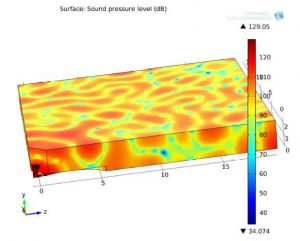

COMSOL, the Acoustics and CAD Import modules are a later generation of FEA software. This software has more advanced meshing algorithms, has near field to far field transformation and calculation of polar responses and beam angles. Turn-around time from CAD model to simulated results is typically less than half a day, enabling many more design iterations to be explored.

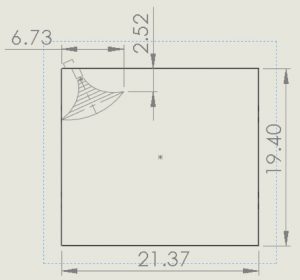

A venue in Bondi Junction Sydney presented an interesting challenge:

COMSOL Multiphysics, especially the acoustics module, has become progressively easier to use; likewise the post processing to obtain frequency responses on and off-axis, and polar and beam angle graphs to assess the performance of the horn design before prototyping.

Good agreement between simulated and measured results has enabled tooling, successful production and a speedy time to market.